Beschreibung

Rubber & Silikon molding is a manufacturing process whereby an amount

of uncured rubber or silicone is transformed into a usable product.

Es gibt 3 Arten von Gummi- und Silikonformverfahren:

-Gummi-Formpressen

Placing a predetermined

amount of rubber compound directly into the mold cavity and then compressing it

into the shape of the cavity by closing the two sides of the mold.

-Gummispritzguss

In this Rubber &

Silikon molding process the uncured rubber compound is heated to a liquid

state before being injected into a mold. The product is released by opening the

mold and closing it again to receive the next injection.

-Gummitransferformteil

Während dieses Kautschuk- und Silikonformprozesses wird die ungehärtete Kautschuk- oder Siliziumverbindung in die als "Topf" bezeichnete Form gegeben, bevor sie durch eine Öffnung in die Form des gewünschten Produkts gedrückt wird. Nach dem Aushärten spaltet die Form das Endprodukt.

Material from Auwell for Rubber & Silikon molding:

-Nitril oder Buna-N

Die beliebteste und kostengünstigste Lösung für das Formen von Gummi und Silikon

-Hydriertes Nitril

This is a more expensive

hydrogenated variation of Nitrile polymer, which increases its resistance to

heat, petroleum products, and ozone almost fivefold.

-Ethylen-Propylen-Dien-Monomer (EPDM)

Commonly used in rubber

molded products for steam systems, vehicles panel seals, and braking systems

due to its high resistance to brake fluid

-Silikon

Resistant to exposure to

high and low temperatures, is very flexible and has good weather resistance.

-Fluorsilikon

Combines the temperature

range advantages of silicone with the resistance to oil, fuel, and solvents

found in fluorocarbons.

-Neoprene

As a strong multi-purpose

material, it can be used in a large number of rubber molding solutions. It has

good fire resistant and abrasion properties and is frequently used in the

manufacture of mass transit and transportation equipment

-Natürliches Gummi

Ein Naturprodukt aus Latex aus dem Kautschukbaum

-SBR (Styrene butadiene)

One of the more

cost-effective polymers that can be used in rubber molding and is frequently

used in the production of tires, diaphragms, seals and gaskets and the mass

production of other rubber parts

-Fluorkohlenwasserstoff

Diese relativ teure Gummimischung kombiniert einen weiten Bereich chemischer Beständigkeit und Hochtemperatureigenschaften.

-Butyl

Hat eine hohe Beständigkeit gegen Gasdurchlässigkeit. Dies macht es zur idealen Lösung bei der Herstellung von Dichtungen für Hochdruckgas- und Vakuumsysteme

-Urethan

Ein ziemlich teures, aber häufig verwendetes Material für Anwendungen, die hohen Druck- und konstanten Stoßbelastungen ausgesetzt sind

Advantages

-Rich Experience

More than 20 years of

experience in Rubber & Silikon molding parts development and part

production, especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-Fast Turnaround

In der Regel bieten wir Aquotation innerhalb von 3 Werktagen an. Auwell kombiniert die neuesten Fertigungstechnologien und -anlagen und ist in der Lage, innerhalb von 5 Arbeitstagen schnelle Prototypen bereitzustellen. Für einfache und kleine Werkzeuge können wir innerhalb von 2 Wochen das erste Muster liefern.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for Rubber & Silikon molding parts development

starting from designing, through prototyping, tooling/fixture development,

sampling, mass production, and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection for Rubber & Silikon molding parts orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request. We

structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Flexible Zahlungsfrist

For tooling, the general

payment term is 50%-50%, meant 50% deposit, 50% after first sample free. For

mass production, we offer flexible payment terms, reasonable credit terms will

be given, the client only pays when they are happy with the product they

received. For long-term projects, we offer call-off inventory services for fast

delivery requirements.

Verwandte Produkte

Kunststoffspritzguss für Autoteile

Kunststoffspritzguss für Autoteile

Plastic Injection Parts

Plastic Injection Parts

Plastic Injection Overmolding

Plastic Injection Overmolding

Plastic Thermoforming Parts

Plastic Thermoforming Parts

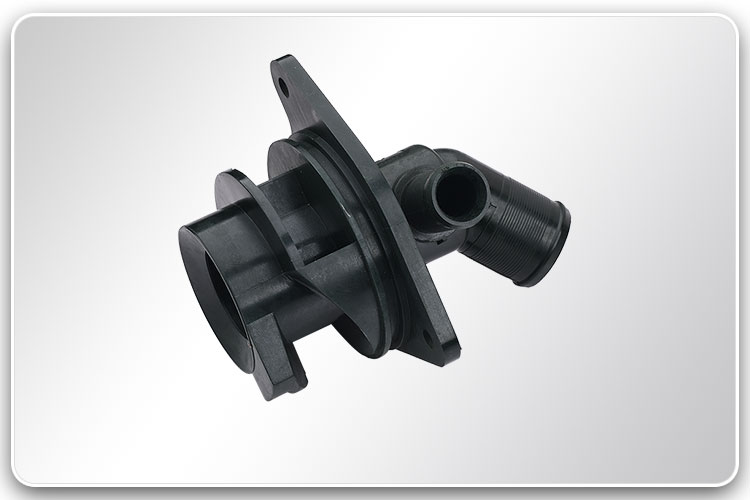

The following catalogues of Rubber & Silikon molding parts are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик